A major application for liquid dispensing systems is drug addiction management. Clinics and centers detoxifying patients from opioid addictions often utilize methadone. As reported in 2011 by the National Survey of Substance Abuse Treatment Services, over 306,000 people in the United States receive methadone for substance abuse each year. This medication helps to minimize narcotic withdrawal symptoms and decrease cravings, all without producing the same euphoric effects as drugs like heroine or prescription painkillers.

Administering methadone requires a strict protocol where exact dosages are consistently taken at a scheduled time. When this protocol isn’t followed, there is a risk of overdose. In fact, there are about 5,000 methadone overdose deaths each year, according to Time Magazine (2012).

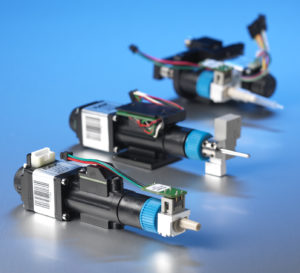

IVEK has a complete line of methadone dispensers to meet the diverse needs of our customers. All our systems are durable, accurate, and user-friendly. Our most popular system, the Digispense DS1000, is capable of extremely high precision and repeatability. This system features positive displacement ceramic pumps and a whisper-quiet, high-speed brushless DC motor. With only one moving part in the fluid path, systems operate for many years without measurable wear. Also included are factory-made tubing kits with bottle cap connections and a volumetric flask for accuracy checks. The DS1000 is easy to control from the USB or RS232 Interface, which is supported by most addiction treatment software.

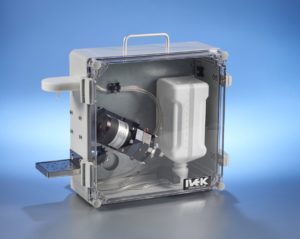

For customers who need a more transportable option, we recently released an all-in-one Controlled Substance Dispensing Station (CSDS). This station is portable, secure and easy to clean. It features shorter tubing runs for faster priming and less waste, a fixed dispense tip for no mess dosing, lockable latches, and adjustable spill tray locations for varying cup sizes. We’re currently offering FREE installation and calibration of your existing pump with any CSDS purchase. Continue Reading

IVEK’s products are used for fluid dispensing across multiple applications and industries. IVEK pumps are used in many industries including medical and pharmaceutical applications, battery manufacturing, food processing, semi-conductor manufacturing, automotive applications, and many others.

IVEK’s products are used for fluid dispensing across multiple applications and industries. IVEK pumps are used in many industries including medical and pharmaceutical applications, battery manufacturing, food processing, semi-conductor manufacturing, automotive applications, and many others.

Usually we try to stay away from any type of valve, since our pumps are valveless and act as their own valve. Recently we ran into a situation where the customer could not purge after the pump was in an idle state for a long period of time (approximately 20-30 minutes). The material was very expensive and hazardous. Moving the reservoir helped a little bit, but regardless the fluid was either going to move forward and drip or move backwards and would then force the user to “waste“ several shots to prepare the pump to dispense again.

Usually we try to stay away from any type of valve, since our pumps are valveless and act as their own valve. Recently we ran into a situation where the customer could not purge after the pump was in an idle state for a long period of time (approximately 20-30 minutes). The material was very expensive and hazardous. Moving the reservoir helped a little bit, but regardless the fluid was either going to move forward and drip or move backwards and would then force the user to “waste“ several shots to prepare the pump to dispense again.

When deciding which OEM pump is best for precise aspirating and dispensing of samples and reagents in both Analytical and IVD instruments, we are often asked the differences between traditional Syringe Pumps and IVEK’s Ceramic Displacement Pumps. Since both of these can be used to do the same function, what are the pros and cons of each?

When deciding which OEM pump is best for precise aspirating and dispensing of samples and reagents in both Analytical and IVD instruments, we are often asked the differences between traditional Syringe Pumps and IVEK’s Ceramic Displacement Pumps. Since both of these can be used to do the same function, what are the pros and cons of each?